How Consistent strapping machine service Ensures Long-Term Operational Success

Wiki Article

Discover the Advantages of Routine Strapping Machine Service for Enhanced Effectiveness and Long Life

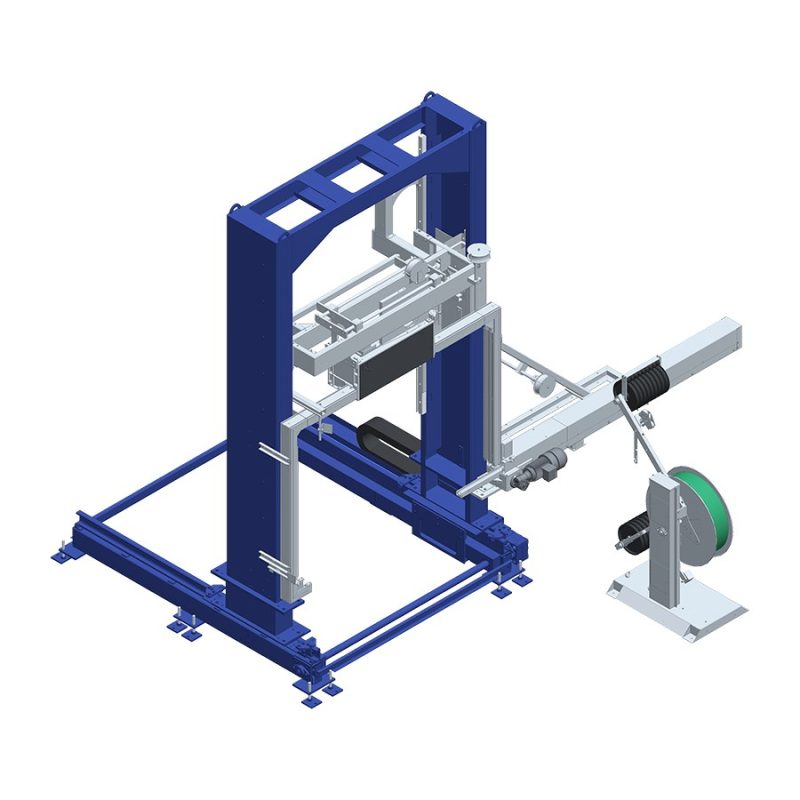

Normal strapping machine service plays a critical role in enhancing manufacturing operations. Companies that prioritize maintenance experience boosted efficiency and lowered downtime. This proactive method can aid determine possible issues early, leading to substantial expense savings. Nonetheless, numerous companies ignore the importance of consistent service. Recognizing the full range of benefits can reshape functional approaches and boost general performance. What are the essential advantages that originate from this essential technique?Comprehending the Importance of Strapping Machine Maintenance

While many companies prioritize production performance, the relevance of strapping machine upkeep usually goes forgotten. Normal upkeep is important for guaranteeing that strapping makers run at peak performance degrees. Neglecting this aspect can result in unexpected breakdowns, which interfere with process and rise downtime. Appropriate upkeep aids to recognize deterioration prior to it escalates right into major concerns, ultimately extending the lifespan of the devices. Furthermore, regular checks guarantee that the devices generate consistent, high-quality strapping, minimizing the danger of damage to items throughout shipping and storage. By investing time and sources into upkeep, organizations can stop expensive repair work and promote a more reliable production setting, thus supporting overall operational objectives over time.Boosted Operational Effectiveness

Boosted functional performance is a vital advantage of normal strapping machine service. By making certain that equipments are properly maintained and working properly, services can greatly reduce downtime caused by breakdowns or ineffectiveness. Regular servicing assists recognize and resolve prospective issues prior to they intensify, enabling smooth procedures. This aggressive strategy indicates that strapping devices operate at peak performance, facilitating quicker manufacturing cycles and decreasing the dangers related to unanticipated break downs. Additionally, a well-tuned machine can handle enhanced work without endangering top quality, enabling better throughput. Ultimately, improved operational efficiency equates right into a much more streamlined operations, equipping companies to meet need successfully and enhance total efficiency in their product packaging procedures. Routine servicing consequently plays an essential function in accomplishing functional excellence.Expense Financial Savings With Preventative Upkeep

Regular maintenance of strapping devices not just boosts operational performance yet also results in substantial cost savings with preventative upkeep. By recognizing and dealing with minor issues before they intensify right into significant troubles, firms can avoid costly repairs and downtime - strapping machine service. Normal evaluations help ensure that elements operate at peak performance, reducing the danger of unanticipated failings that can interrupt manufacturing routines. Additionally, consistent upkeep can cause much more reliable energy use, decreasing energy expenses with time. Reliable preventative maintenance techniques likewise allow businesses to prepare their budgets better, as expenditures end up being a lot more foreseeable. Inevitably, buying routine service equates to lasting economic advantages, making it a wise strategy for any organization reliant on strapping machineryExtending the Life Expectancy of Your Tools

Routine maintenance checks play a necessary duty in extending the life-span of strapping machines. Prompt fixings and making use of quality substitute parts additionally assure that tools continues to be in ideal condition. By focusing on these techniques, services can substantially enhance the toughness and reliability of their strapping equipments.Routine Upkeep Checks

Strapping machines are made for toughness, overlooking normal maintenance checks can substantially reduce their life expectancy. Regular assessments assist determine wear and tear before they escalate right into substantial problems. Routine maintenance guarantees that all components function at their best, decreasing the risk of unexpected failures and improving total performance. Throughout these checks, components such as motors, sensors, and belts can be cleansed and lubed, preventing rubbing and overheating. Furthermore, calibration of the machine setups can be carried out to maintain exact operation, more extending its long life. By establishing a routine upkeep routine, organizations can assure their strapping makers run successfully, saving time and reducing costs connected with devices failing. Eventually, regular upkeep checks are essential for taking full advantage of the lifespan and reliability of strapping makers.Prompt Repair Works Value

Prompt repairs are important for preserving the functional performance and long life of strapping machines. When issues occur, addressing them promptly avoids minor issues from intensifying into significant breakdowns that can bring about expensive downtime. Regular maintenance allows operators to identify wear and tear early, ensuring machines work effectively. Prompt repair work aid preserve the high quality of strapping processes, which is essential for product honesty and client contentment. Disregarding repair services visite site can lead to increased power usage and decreased performance, negatively influencing general functional expenses. By focusing on timely fixings, companies can expand the life expectancy of their strapping equipment, inevitably safeguarding their financial investment and enhancing overall performance in assembly line. Consistent attention to fixings is vital to sustained efficiency.Top Quality Substitute Components

Buying quality replacement parts is crucial for expanding the life-span of strapping devices. Top notch components assure peak performance and dependability, lowering the possibility of failures and pricey repair services. When substandard parts are used, they can cause added strain on the machinery, leading to even more constant failures and a much shorter operational life. Additionally, top quality substitute parts typically come with much better service warranties, offering added satisfaction for drivers. Using original equipment maker (OEM) components can additionally boost compatibility and efficiency, making certain that the strapping machine runs as planned. Normal maintenance, integrated with using top quality parts, produces a collaborating result that takes full advantage of effectiveness, lowers downtime, and eventually adds to the lasting success of the organization.

Reducing Downtime and Interruptions

As manufacturing schedules become progressively demanding, decreasing downtime and interruptions in strapping machine procedures is crucial for keeping effectiveness. Routine maintenance of strapping makers can considerably decrease the chance of unexpected failures. Set up upkeep permits early discovery of potential problems, ensuring that all elements operate at their ideal. This positive technique not only stops costly stops in production but additionally expands the life-span of the equipment. Furthermore, well-kept makers run smoothly, decreasing the possibilities of functional hiccups that could interrupt process. By website link buying regular service, businesses can produce a more reliable manufacturing setting, enhancing total performance and conference limited distribution due dates. Ultimately, lessening downtime through regular maintenance methods is crucial for sustaining reliable strapping procedures.Making Sure Consistent High Quality and Performance

While keeping a high degree of efficiency, making sure regular top quality and performance in strapping makers is necessary for any type of assembly line. Routine servicing plays a vital role in this element, as it helps identify click to investigate and fix prospective problems prior to they intensify. A properly maintained strapping machine supplies consistent tension and safe seals, which are critical for packaging stability. On top of that, constant efficiency decreases the danger of item damage throughout transport, ultimately boosting client fulfillment. By purchasing routine upkeep, companies can optimize their strapping operations, making certain that equipment operates at peak capability. This proactive method not just prolongs the lifespan of the devices however additionally assures that production criteria are fulfilled regularly, fostering dependability in the total production process.Frequently Asked Questions

Exactly How Often Should Strapping Machines Be Serviced?

Strapping machines ought to ideally be serviced every six months to assure peak efficiency. Usage frequency and functional conditions may necessitate extra frequent examinations, assuring longevity and efficiency in their operation.What Are Typical Signs That My Strapping Machine Needs Servicing?

Typical indications that a strapping machine requires servicing include constant jams, irregular tension, uncommon noises, visible wear on parts, and unpredictable procedure. strapping machine service. Resolving these problems without delay can prevent additional damages and guarantee peak efficiencyCan I Carry Out Upkeep on My Strapping Machine Myself?

Yes, a person can do fundamental maintenance on a strapping machine, such as cleansing and lubrication. However, for considerable repair work or maintenance, professional aid is recommended to assure peak efficiency and long life.What Kinds of Strapping Machines Require Service?

Numerous kinds of strapping makers, including semi-automatic, automated, and handheld models, require normal service. Each type might have special upkeep requirements, but all advantage from routine checks to assure peak efficiency and longevity.

Exist Certain Provider for Various Strapping Machine Brands?

Yes, specific provider often focus on different strapping machine brands. These companies have the essential experience and components to assure peak repair and maintenance tailored to the special needs of each brand's tools.Enhanced operational effectiveness is a crucial advantage of normal strapping machine service. Normal maintenance of strapping equipments not only boosts functional performance however additionally leads to significant price financial savings through preventative upkeep. Routine maintenance checks play an important duty in prolonging the lifespan of strapping equipments. By establishing a regular upkeep schedule, businesses can assure their strapping devices run efficiently, saving time and reducing expenses linked with equipment failing. Yes, an individual can carry out fundamental maintenance on a strapping machine, such as cleansing and lubrication.

Report this wiki page